If you think microchips are ubiquitous now, appearing in everything from washing machines to lampposts, just wait until circuits can be printed onto plastic, paper, and fabric for the price of pennies. That’s what chip designer Arm is promising, with the company this week unveiling a new prototype plastic-based microchip named PlasticARM.

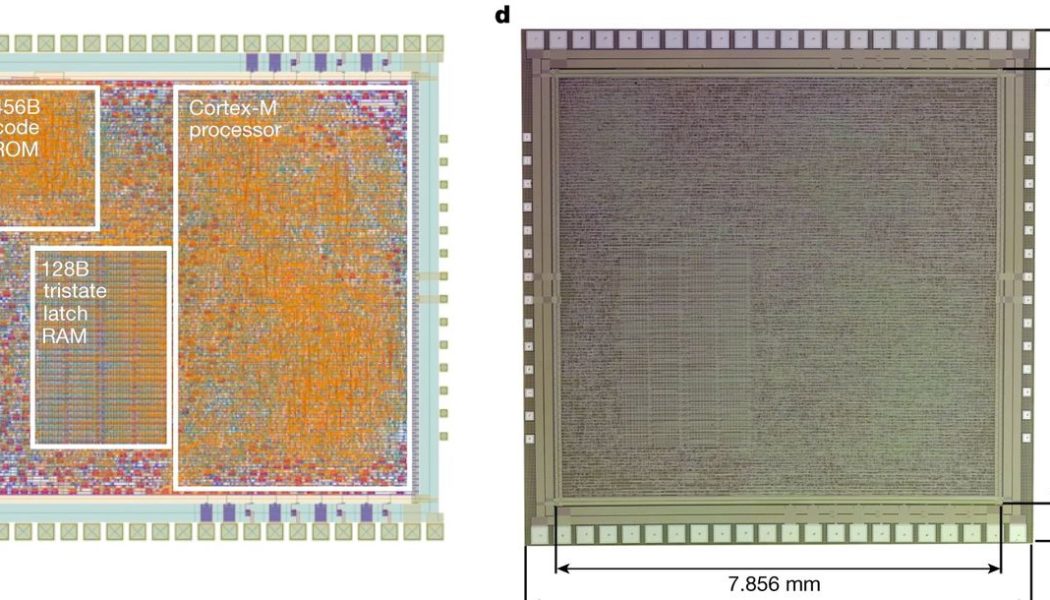

This isn’t the first flexible chip we’ve seen, but it is the most complex. PlasticARM contains a 32-bit Cortex-M0 CPU (the cheapest and simplest processor core in Arm’s Cortex-M family), as well as 456 bytes of ROM and 128 bytes of RAM. It’s comprised of over 18,000 logic gates, which Arm says is at least 12 times more than the previous plastic-based chip.

The chip was designed in coordination with flexible electronics maker PragmatIC, and as the company’s designers explain in a paper published in Nature, it doesn’t yet have the same functionality of silicon-based designs. For example, it’s only capable of running a trio of test programs hardwired into its circuits during fabrication, though Arm’s researchers say they’re working on future versions that will allow new code to be installed.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/22735203/plasticarm.jpg)

What makes PlasticARM and similar chips so special is their use of flexible components; in this case, metal-oxide thin-film transistors or TFTs. These can be printed onto surfaces that bend and flex without degrading, unlike processors based on brittle silicon substrates. This makes it possible to cheaply print processors onto materials like plastic and paper.

As Arm’s researchers explain in their paper, this would allow microchips to be put to all sorts of uses that would seem wasteful today. You might have chips printed into every milk bottle for example that detect spoilage, replacing the use of sell-by-dates. Arm says this will create a new “internet of everything,” with chips integrated into “more than a trillion inanimate objects over the next decade.”

Plastic-based chips have major drawbacks, though, and will certainly not replace silicon processors in the short term. They’re simply too inefficient in terms energy consumption, density, and performance. PlasticARM consumes 21 milliwatts of power, for example, but 99 percent of that is essentially wasted, with only 1 percent captured for computation. The chip is also comparatively large, with an area of 59.2 square millimeters. As noted by AnandTech, that’s around 1,500 times the size of a silicon-based Cortex M0 processor.

As Arm research engineer James Myers told New Scientist: “It won’t be fast, it won’t be energy efficient, but if I’m going to put it on a lettuce to track shelf life, that’s the idea.”